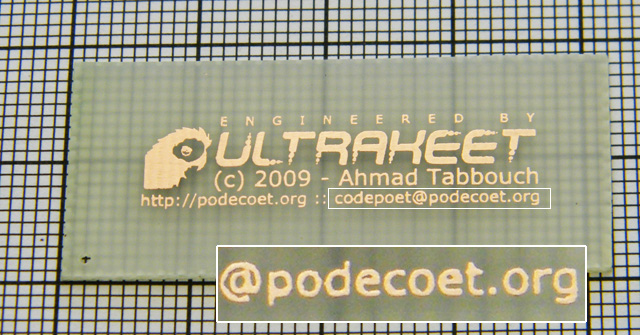

So I ran some tests on both Ferric and Ammonium-based etchants to find the one best suited for finer detail (since the arguments can get quite violent on the web it seems!) - I heated both etchants to the recommended temperatures, and tried various agitation methods. Both boards were produced using the exact same Toner-Transfer method, as well as an additional layer of Green TRF to protect against pitted traces. Note that the grid is 1mm & 10mm

The only method of agitation that yielded usable results for the Ammonium-based etchant was a bubble tank. At such a relatively high etching temperature, any direct contact with the etch-resist causes it to flake away or become pitted, leading to a terrible looking PCB. This also makes it extremely difficult to "touch up" traces with a CD-Marker prior to etching, as the ink gradually dissolves away into the heated solution.

As for Ferric Chloride, while extremely messy and opaque (it stains EVERYTHING!), the etching process was extremely rapid at the recommended temperature of 40oC. There was very little to no undercutting of the PCB traces due to the short exposure to the etchant. Agitation by means of a bubble tank didn't work anywhere near as well as a simple paintbrush, and the etch-resist remained undamaged via either method, likely due to the lower etching temperature.

The proof is in the pictures above! Which would you choose?